|

全伺服智能开槽碰线机

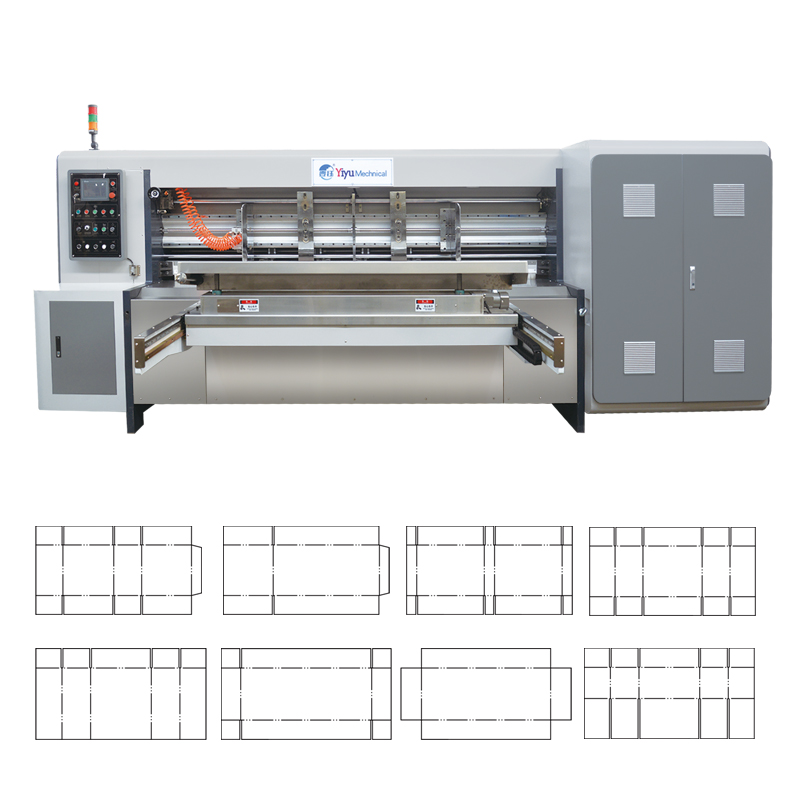

收藏

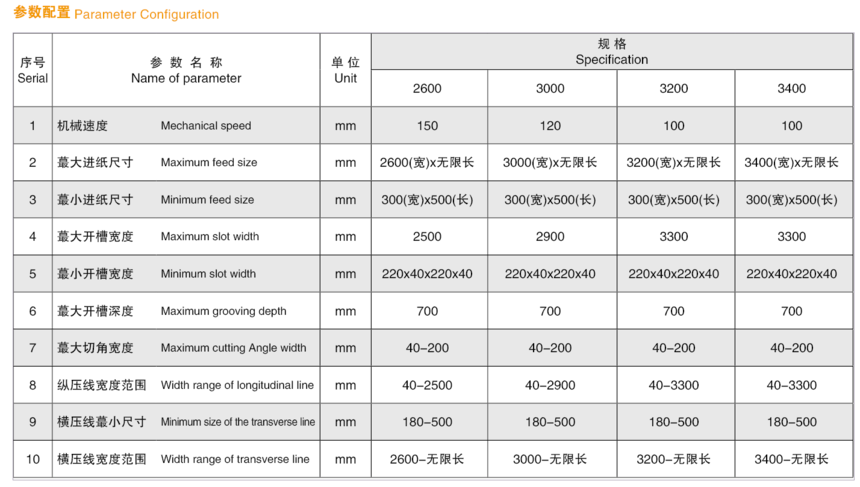

★本机是一台高/端智能双模切开槽碰线纸箱机械,根据纸箱行业的发展需要精心研制而成并投放市场,深受市场的一致好评。 主要针对家具箱及大规格纸箱和数码印刷及其他散单产品,该机器为客户解决了特大家具箱、特殊纸箱的生产难题。 ★机器主要功能可一次完成三层、五层、七层瓦楞纸板:送纸、预压、压线、开槽、打孔、碰线、修边、切高低舌头。 ★纸箱开槽有两排刀座完成(前刀开前槽,后刀开后槽)可以完成高低盖,采用上模切刀,下优力胶垫辊及碰线,生产时纸箱 正面朝下,成品后的纸箱外表美观。 ★整个机器由伺服电机和 PLC 触摸屏控制操作方便简单,可生产多款箱型,一键换单 20秒之内完成。 ★前缘送纸采用伺服电机,确保送纸精度。双开槽部五刀盘分别由独立的伺服电机控制,前后两根刀轴由伺服电机单独控制, 纵压线轴由伺服电机控制。主电机采用变频电机,前缘吸风机变频调整变频器控制风量。 ★该机蕞主要特点是蕞小压线开槽宽度为40mm(其他机型:60-90mm),切角蕞大宽度200mm(其他机型50-100mm) 碰线蕞小间距 180mm 碰线槽盖 40mm 速度为100 米。 ★机器设计成三组(前缘送纸、双开槽部、碰线部)。 ★ This machine is a high-end intelligent double-mode grooving touch line carton machinery, according to the development of the carton industry needs to carefully developed and put into the market, by the market praise. Mainly for furniture boxes and large size cartons and digital printing and other loose single products, the machine for customers to solve the production problems of large furniture boxes, special cartons. ★ The main function of the machine can complete three, five, seven layers of corrugated cardboard at a time: paper feeding, pre-pressing, line pressing, grooving, punching, touching line, trimming, cutting high and low tongue. ★The carton is slotted with two rows of knife seats (the front knife is slotted before, the back knife is slotted after) can complete the high and low cover, the upper die cutting knife, the lower force rubber cushion roll and the touch line, the carton face down when the production, the carton looks beautiful after the finished product. ★The whole machine is controlled by servo motor and PLC touch screen, which is convenient and simple to operate. It can produce many types of boxes. ★Servo motor is used in leading edge feeding to ensure the accuracy of feeding. The five cutter heads of the double slotted part are respectively controlled by independent servo motors, the front and rear cutter shafts are separately controlled by servo motors, and the longitudinal pressure bobbin is controlled by servo motors. The main motor adopts frequency conversion motor, and the leading edge suction fan is adjusted by frequency conversion to control the air volume. ★The main feature of this machine is the minimum pressure line slot width of 40mm(other models: 60-90mm), the maximum width of cutting Angle of 200mm(other models 50-100mm) the minimum distance between 180mm touch line slot cover 40mm speed of 100 meters. ★The machine is designed into three groups (leading edge feeding, double slotting part, longitudinal line part).

送纸单元Paper feeding unit ★前缘送纸采用英国 CT 伺服系统,无线延长纸板长度,确保送纸精度。 ★四轴前缘送纸加大吸风流量,送纸更平稳、准确。 ★左右挡板及后挡板自动调整。 ★精/准缓压送纸,减少纸板强度损伤。 ★自动调整送纸行程,减轻拉纸胶辊压力。

★单、双刀盘设计,开槽尺寸由电脑调控,伺服自动调整。 ★中刀移动,可生产多款箱型,并通过主控电脑一键操作完成。 ★双光轴配合双直线导轨,实现各种纸箱尺寸,快稳准。 ★采用上模切刀,下优力胶垫辊,生产时纸箱正面朝下,成品后的纸箱外表美观。 ★八轴设计自动调整预压→模切后刀→压线→模切前刀。 ★胶垫辊机械式横移装置。 ★Single and double cutter head design, slot size is controlled by computer, servo automatic adjustment. ★In the knife movement, can produce a variety of boxes, and through the main control computer one-click operation. ★Double optical axis with double linear guide rail, achieve a variety of carton sizes, fast and stable. ★Adopt the upper die cutting knife, the lower Youli rubber pad roller, the production carton face down, the finished carton appearance is beautiful. ★Eight axis design automatic adjustment of preload → die cutting knife → press line → die cutting knife。 ★Rubber pad roller mechanical transverse movement device。

碰线单元Line touching unit ★碰线设计由六轴自动调整。 ★伺服独立驱动,单轴双线或双轴双线。 ★送纸采用英国 CT 伺服系统,确保碰线精度。 ★送纸开槽过程中可同时完成双线或四线及多线。 ★The touch line design is automatically adjusted by six axes. ★Servo drive independently, single axis double line or double axis double line. ★Paper feeding adopts British CT servo system to ensure line touch accuracy. ★In the process of paper feeding and grooving, double or four lines and multiple lines can be completed simultaneously. |

开槽单元Slotting unit

开槽单元Slotting unit